CNC Milling Machine

MIE243 (University of Toronto) is an introduction to basic mechanical parts and mechanisms: gears, cams, bearings, linkages, actuators and motors, chain and belt drives, brakes and clutches, hydraulics and pneumatics. Conceptual design examples and mechanical engineering design process, including selection and applications of mechanisms are explained. In small groups of four students, we developed an advanced conceptual design for an entry-level professional desktop milling machine. The goal was to create a complete design which is ready to continue into the detailed design process.

We chose our audience to be the automotive industry. We wanted our machine to be designed for rapid prototyping and creating parts not mass produced. Through iteration, we developed candidate designs that satisfied the engineering specifications we defined. Then, we passed to the detailed design where we selected the different mechanisms of the machine in order to optimize the performance and cost of the machine.

Contribution & Outcome

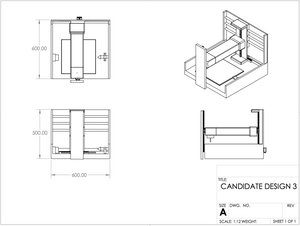

The candidate design I developed (See Gallery on the right) was a 4 axis CNC milling machine equipped with a coolant and a tool changer, The coolant was necessary since our primary used material being metals, cutting through them will generate heat due to friction. The tool changer would allow a great facility for rapid prototyping by being able to run time consuming parts during the night with no need to change tools. The 4th axis allows the creation of complex shapes needed in the automotive industry. I built the SolidWorks file to demonstrate those mechanisms, by using both standard parts bought from vendors and custom parts designed by me. All of that optimizing cost, machine to sample volume and accuracy. It was a great chance to practice and develop my designing and CAD skills while working with different people from which I learned a lot.